Скачать с ютуб What is VMI - Vendor Management Inventory в хорошем качестве

Скачать бесплатно и смотреть ютуб-видео без блокировок What is VMI - Vendor Management Inventory в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно What is VMI - Vendor Management Inventory или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон What is VMI - Vendor Management Inventory в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса ClipSaver.ru

What is VMI - Vendor Management Inventory

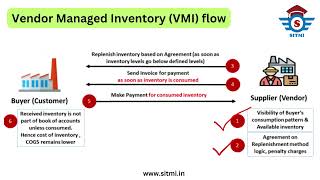

Experience the power of Vendor Managed Inventory ( VMI ) in revolutionizing supply chain management. VMI empowers suppliers to oversee and replenish inventory based on your needs, optimizing efficiency and reducing waste in alignment with lean manufacturing principles. Through real-time data sharing, suppliers monitor and manage your inventory levels, ensuring timely replenishment and minimizing excess stock. 📌 Related videos ▶ Inventory Management • What Is Inventory Management ▶ 4 Types of Inventory https://www.leanvlog.com/types-of-inv... ✍ Here is the transcript of the video: ▶ VMI Definition Vendor Managed Inventory (VMI) is a supply chain management strategy where the supplier takes responsibility for managing and replenishing inventory based on the customer's inventory levels and demand forecasts. As an industrial engineer, you would appreciate that VMI aims to optimize the entire supply chain's efficiency and reduce waste, aligning closely with lean manufacturing principles. In a VMI partnership, the vendor monitors the buyer's inventory levels, often through electronic data interchange (EDI) or other real-time data sharing methods. The supplier makes decisions on when to replenish stock and how much to send, within agreed-upon parameters. ▶ VMI Benefits This proactive approach can lead to several benefits: 1. Reduced Inventory Levels: By closely monitoring usage and demand patterns, suppliers can reduce the amount of inventory on hand at the customer's site, thus minimizing carrying costs and the risk of overstocking or stockouts. 2. Improved Service Levels: VMI can lead to more accurate inventory levels, ensuring that the right products are available when needed, which enhances service quality to the end customer. 3. Enhanced Collaboration: VMI fosters a closer relationship between the supplier and the customer, as both parties work together to optimize inventory management, leading to better communication and joint planning. 4. Streamlined Operations: Suppliers can better plan their production and distribution, leading to more efficient operations and potentially lower costs due to economies of scale. 5. Focus on Core Competencies: With suppliers managing inventory, customers can focus more on their core business activities, such as production and sales, rather than on inventory management. ▶ Conclusions For industrial engineers, VMI offers an opportunity to apply systems thinking to the supply chain. It requires a deep understanding of the production process, demand forecasting, and the flow of materials. ツ CONNECT WITH ME ツ Hi, my name is Mark Anderson a 20+ year Lean Expert. I have created LeanVlog because I want to spread Lean Thinking worldwide and I think the video is the most effective way to teach, learn, and spread knowledge. If you want to stay in touch with me you can choose the channel you prefer. A) Linkedin / mark-anderson-leanvlog B) Latest Videos and Playlist Website: https://www.leanvlog.com C) Telegram https://t.me/leanvlog #leanmanagement #vendormanagement #vendormanagementsystem