Скачать с ютуб Learn how to construct material requirement plan (MRP) в хорошем качестве

material requirement planning

bill of materials

product structure tree

MRP

production planning

what is mrp

inputs of material requirement planning

aljazari

al jazari

BOM

inventory management

BOM and inventory

assembly time chart

material requirements planning

mrp

material requirement planning process

operations management

William stevenson

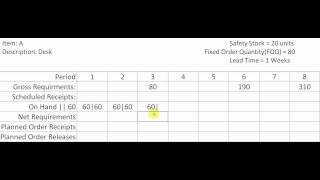

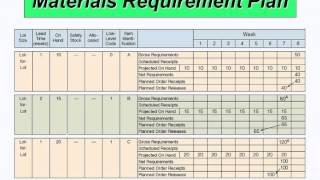

Scheduled receipts

Projected on hand

planned-order receipt

Planned-order release

mrp ii

Скачать бесплатно и смотреть ютуб-видео без блокировок Learn how to construct material requirement plan (MRP) в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно Learn how to construct material requirement plan (MRP) или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон Learn how to construct material requirement plan (MRP) в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса ClipSaver.ru

Learn how to construct material requirement plan (MRP)

Material requirement planning, or MRP, is a process that translates the finished product requirements of the master schedule into time-phased requirements for subassemblies, component parts, and raw materials, working backward from the due date using lead times and other information to determine when and how much to order. To make an MRP, it is required to obtain the necessary number of items to assemble a certain number of end products knowing the product structure tree and the quantity on hand from each item from the inventory record. Then construct the assembly time chart to show material order points needed to meet the scheduled availability of the end item. This video illustrates how to make a product structure tree from the given information and then use it along with the inventory record to find the number of individual items required to assemble a certain number of final products. After that, it illustrates how to use the available information about assembly, subassembly, and individual items' lead time to construct the assembly time chart. Finally, it shows how to construct the MRP to determine the size and timing of planned order releases necessary to meet delivery requirements If you want to improve your business process or produce better-quality products in the desired time, then you need to watch this video! By learning about MRP and product structure tree, you'll be able to assemble your products in a timely manner, ensuring customer satisfaction! So tune in, and learn how MRP can help you assemble your product faster and with fewer errors!