Shaded Pole Motor Plastic Bobbin Coil Winding & Soldering Machine – 16 Spindle | Blower, Exhaust Fan скачать в хорошем качестве

Повторяем попытку...

Скачать видео с ютуб по ссылке или смотреть без блокировок на сайте: Shaded Pole Motor Plastic Bobbin Coil Winding & Soldering Machine – 16 Spindle | Blower, Exhaust Fan в качестве 4k

У нас вы можете посмотреть бесплатно Shaded Pole Motor Plastic Bobbin Coil Winding & Soldering Machine – 16 Spindle | Blower, Exhaust Fan или скачать в максимальном доступном качестве, видео которое было загружено на ютуб. Для загрузки выберите вариант из формы ниже:

-

Информация по загрузке:

Скачать mp3 с ютуба отдельным файлом. Бесплатный рингтон Shaded Pole Motor Plastic Bobbin Coil Winding & Soldering Machine – 16 Spindle | Blower, Exhaust Fan в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием видео, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса ClipSaver.ru

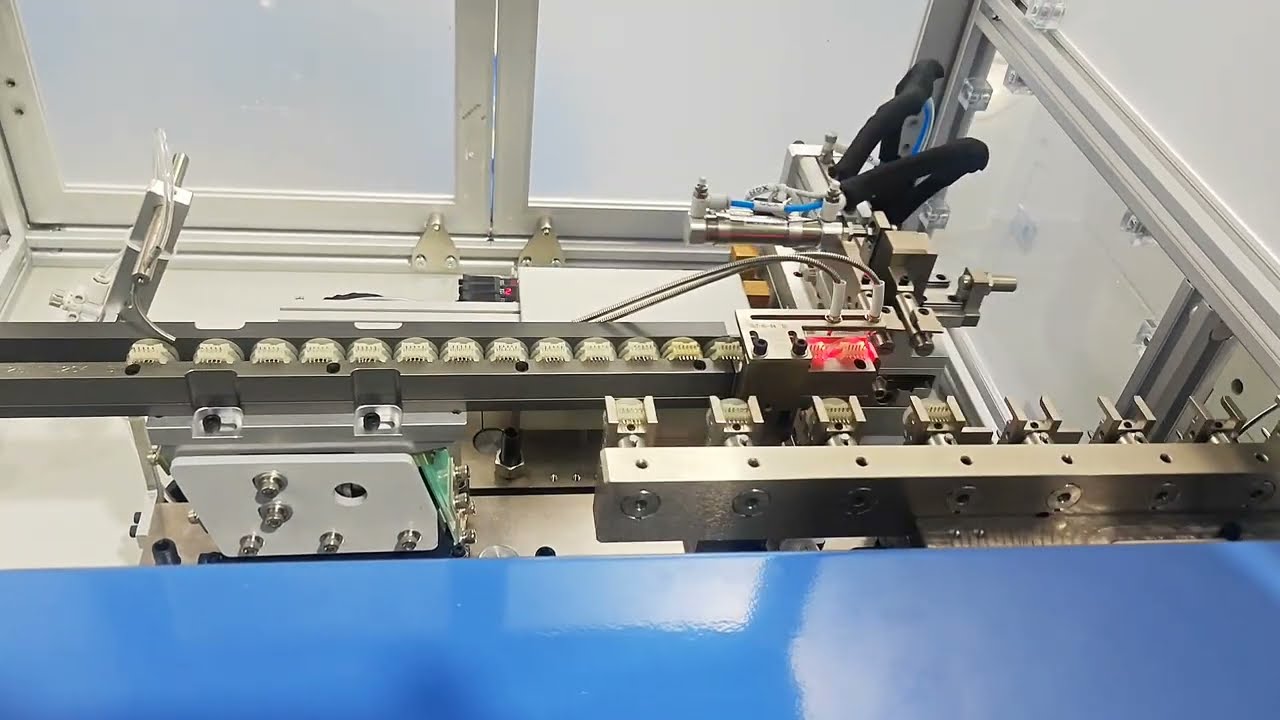

Shaded Pole Motor Plastic Bobbin Coil Winding & Soldering Machine – 16 Spindle | Blower, Exhaust Fan

Shaded Pole Motor Plastic Bobbin Coil Winding & Soldering Machine – 16 Spindle High-Speed Automatic Solution for Mass Production In today’s competitive motor manufacturing industry, speed, consistency, and reliability are critical. Shaded pole motors are widely used in applications such as fans, blowers, cooling systems, exhaust units, refrigerator motors, HVAC equipment, and small appliances, where cost-effective and stable performance is required. To meet high-volume demand with consistent quality, manufacturers need a fully automatic and repeatable coil winding solution. The Shaded Pole Motor Plastic Bobbin Coil Winding & Soldering Machine – 16 Spindle is designed specifically to address these production requirements. This machine integrates high-speed coil winding and precise soldering in a single automated system, making it ideal for mass production environments. ________________________________________ Machine Overview : This machine is a 16-spindle automatic winding system, capable of winding multiple shaded pole motor coils simultaneously. Each spindle operates with synchronized control to ensure uniform turns, stable wire tension, and repeatable coil geometry across all bobbins. The system is engineered for plastic bobbin coils, which are commonly used in shaded pole motor construction. By combining automatic winding and soldering, the machine significantly reduces manual handling, operator dependency, and quality variation. ________________________________________ Key Working Process 1. Plastic Bobbin Loading Plastic bobbins are loaded into the winding spindles, either manually or via an optional automatic feeding system. 2. Automatic Coil Winding (16 Spindle) o Simultaneous winding on 16 spindles o Programmable turns, speed, and acceleration o Controlled wire tension for consistent coil shape o High repeatability across all spindles 3. Automatic Lead Management Lead wire length and positioning are controlled to ensure proper soldering and easy motor assembly. 4. Integrated Soldering Process o Flux application for proper solder wetting o Dip soldering for strong and reliable joints o Consistent solder quality across all coils 5. Finished Coil Unloading Completed coils are unloaded and ready for the next motor assembly process. ________________________________________ Major Features • 16 Spindle High-Output Design for maximum productivity • Precise Turn Count Control with electronic accuracy • Stable Wire Tension System to prevent loose or uneven winding • Integrated Soldering Unit for reliable electrical connections • PLC & HMI Control System for easy operation and recipe management • Quick Changeover Capability for different bobbin sizes and coil designs • Low Operator Dependency, ideal for long production runs ________________________________________ Advantages for Manufacturers • High Production Rate Multiple coils produced in a single cycle, increasing output per shift. • Consistent Quality Automated winding and soldering ensure uniform electrical and mechanical characteristics. • Reduced Labor Cost One operator can manage the complete machine. • Improved Reliability Strong solder joints and controlled winding reduce field failures. • Repeatability & Process Stability Ideal for OEMs supplying motors to large appliance brands. ________________________________________ Typical Applications • Shaded pole motors for fans and blowers • HVAC and refrigeration motors • Exhaust fans and ventilation systems • Small appliance motors • Cooling motors for electrical and electronic equipment ________________________________________ Why Automation Matters in Shaded Pole Motor Manufacturing Manual or semi-automatic winding processes often lead to: • Variation in turn count • Inconsistent solder joints • Higher rejection rates • Operator fatigue and dependency The 16 Spindle Shaded Pole Motor Coil Winding & Soldering Machine eliminates these issues by providing a fully controlled, automated, and repeatable production process, suitable for continuous industrial operation. ________________________________________ Final Thoughts : If you are looking to scale up shaded pole motor production while maintaining quality, consistency, and efficiency, this machine is a proven solution. With its 16-spindle high-speed winding, integrated soldering, and robust industrial design, it helps manufacturers achieve higher output, lower rejection, and faster ROI. This machine is an excellent choice for companies aiming to modernize their motor coil production and stay competitive in today’s demanding market. ________________________________________ Contact Us : ✅ Ready to Automate Your Coil Manufacturing in India? 📞 Contact : DepTronics Technologies 🌐 https://coilwinder.in/ 📧 sales.deptronics@gmail.com 📱 WhatsApp or Call : +91-8800622761 #shadedpole #synchronousmotor #coilwinding #motorbobbin #motorcoil #ShadedPoleMotor #FanMotorCoil #BobbinCoil #MotorCoilWinding #ExhaustFanMotor #BlowerMotor #CoilWindingMachine