5 Flange Facing types must-know for every engineer скачать в хорошем качестве

Скачать видео с ютуб по ссылке или смотреть без блокировок на сайте: 5 Flange Facing types must-know for every engineer в качестве 4k

У нас вы можете посмотреть бесплатно 5 Flange Facing types must-know for every engineer или скачать в максимальном доступном качестве, видео которое было загружено на ютуб. Для загрузки выберите вариант из формы ниже:

-

Информация по загрузке:

Скачать mp3 с ютуба отдельным файлом. Бесплатный рингтон 5 Flange Facing types must-know for every engineer в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием видео, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса ClipSaver.ru

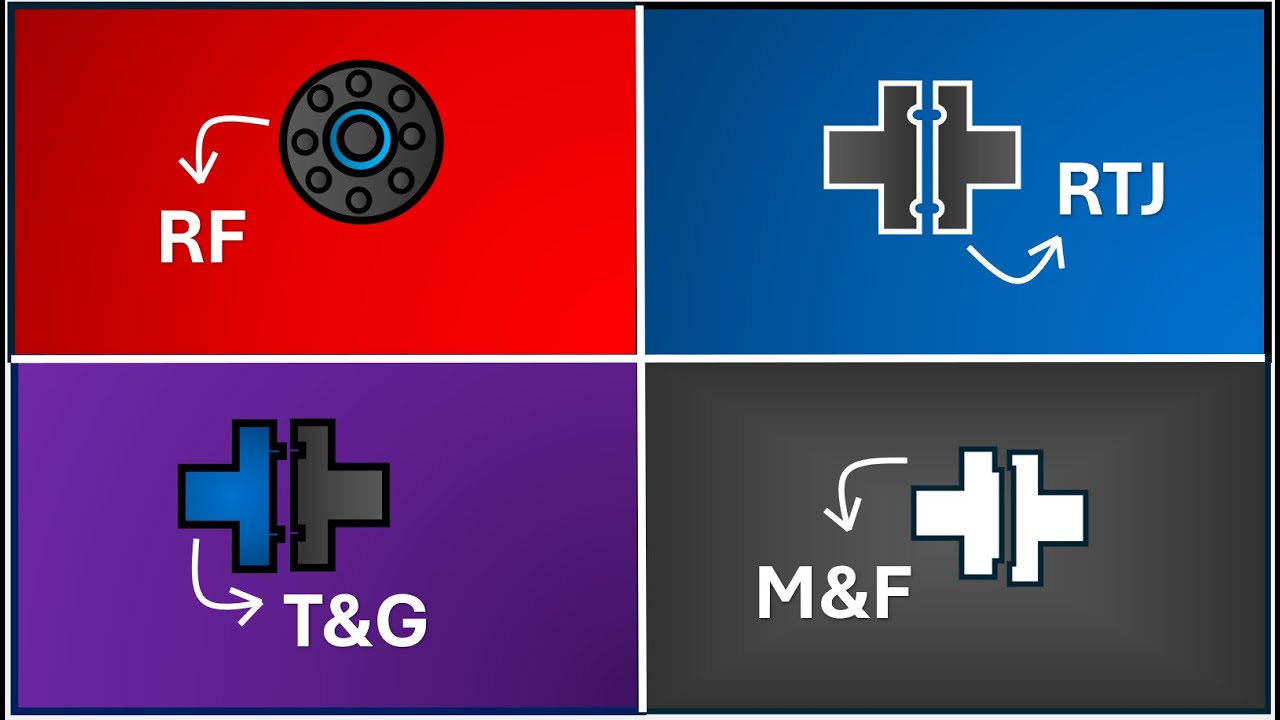

5 Flange Facing types must-know for every engineer

🔴 FREE E-book on Control Valves 👉Link to Download : https://www.asad-shaikh.com/control-v... ( 🔴 ) Link to FREE Udemy Course for I&C Professionals 1500+ Engineers have taken the Course (Engineers have said it is even BETTER than the PAID Courses available) Give it a Try 😊 Link 👉 https://asad-shaikh-instrumentation.c... Flat Face (FF): The Flat Face flange facing is characterized by a smooth, flat surface perpendicular to the pipe axis. It is suitable for low-pressure applications where sealing is achieved with a gasket between the flange faces. Flat face flanges are easy to align and provide a large contact area for the gasket, ensuring a reliable seal. Raised Face (RF): The Raised Face flange facing features a raised portion around the bore, creating a step that provides additional contact surface for the gasket. This facing type is suitable for moderate pressure and temperature applications. The raised face helps protect the gasket and provides a more effective seal compared to flat face flanges. Tongue and Groove (T&G): Tongue and Groove flange facing consists of a raised ring (tongue) on one flange face and a matching depression (groove) on the other. When the two flanges are mated, the tongue fits into the groove, creating a tight seal without the need for a gasket. T&G flanges are often used in applications where leakage prevention is critical, such as high-pressure and high-temperature environments. Male and Female (M&F): Male and Female flange facing is similar to T&G facing but with a different geometry. The male flange has a raised portion (male face), while the female flange has a matching depression (female face). When assembled, the male face fits into the female face, creating a tight seal without a gasket. M&F flanges are used in applications where leakage prevention and ease of assembly are important factors. Ring Type Joint (RTJ): Ring Type Joint flange facing features a groove around the flange bore where a metal ring gasket is placed. When the flanges are bolted together, the ring gasket is compressed between the flange faces, forming a tight seal. RTJ flanges are commonly used in high-pressure and high-temperature applications where standard gaskets may fail.