CNC Headtube – How Our MTB Frame Lugs Are Really Made скачать в хорошем качестве

Повторяем попытку...

Скачать видео с ютуб по ссылке или смотреть без блокировок на сайте: CNC Headtube – How Our MTB Frame Lugs Are Really Made в качестве 4k

У нас вы можете посмотреть бесплатно CNC Headtube – How Our MTB Frame Lugs Are Really Made или скачать в максимальном доступном качестве, видео которое было загружено на ютуб. Для загрузки выберите вариант из формы ниже:

-

Информация по загрузке:

Скачать mp3 с ютуба отдельным файлом. Бесплатный рингтон CNC Headtube – How Our MTB Frame Lugs Are Really Made в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием видео, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса ClipSaver.ru

CNC Headtube – How Our MTB Frame Lugs Are Really Made

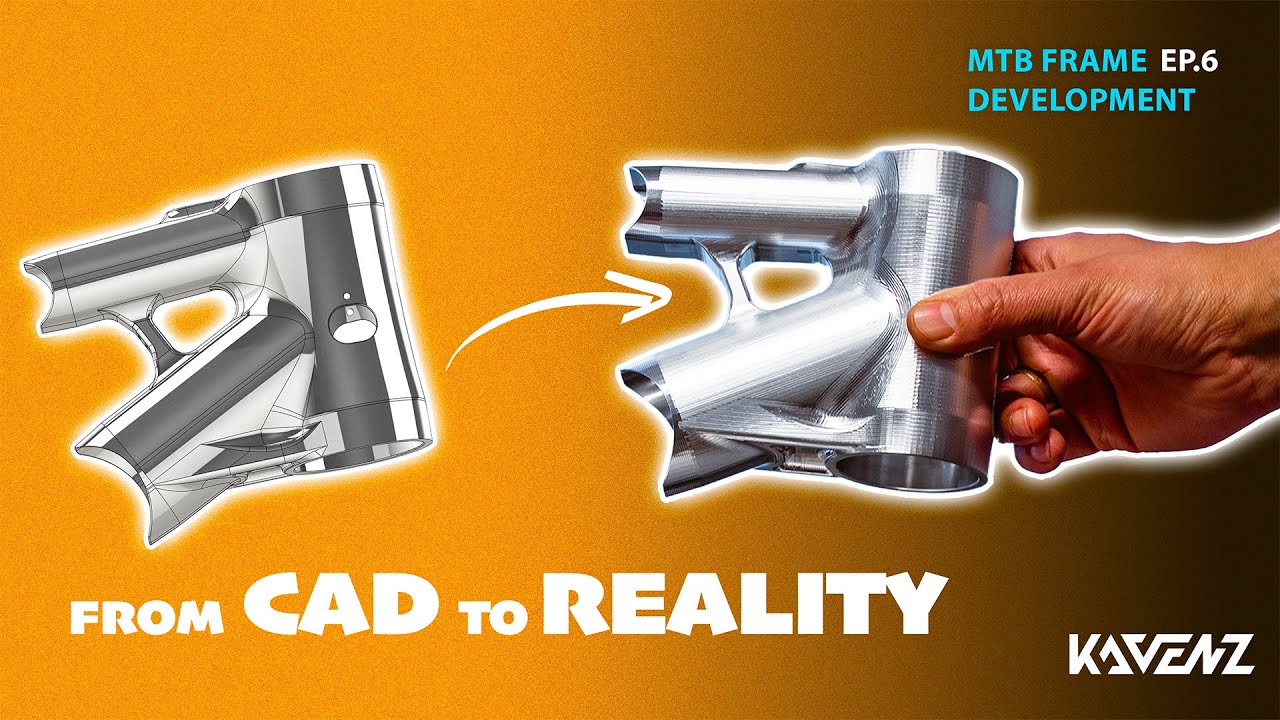

In Episode 6 of our MTB Frame Development series we visit Spantech to show how our lug design goes from a 3D CAD model to a fully CNC-machined part. Spantech first caught our attention when they CNC-machined the one-piece crown for Intend — and with Manuel, who’s deeply involved in programming and machining and also a biker himself, it was clear they understand both the technical and real-world demands of bicycle parts. In this episode we take a close look at: How our FEM-optimised lug geometry is prepared for CNC machining The transition from CAD to CAM and how toolpaths are defined 5-axis CNC machining, clamping strategies and tool choices Weight reduction from raw aluminum block to finished lug Machining times, roughing vs finishing, and where the real costs come from We also explain why we intentionally chose a coarser finishing strategy: It significantly reduces run time and cost — and we genuinely like the look of the visible tool paths. Not every surface needs to be perfectly smooth if it fits the character and function of the frame. The lugs shown here are machined exactly as designed, without any cost-driven geometry changes yet. Now that the feasibility is proven, the next step will be to further cost-optimise the design in order to reach a sweet price point for the complete frame — without compromising strength, precision or aesthetics. This series documents real development decisions, compromises and trade-offs — not marketing claims.