Robotic Depalletizing for Distribution and Fulfillment Warehouses скачать в хорошем качестве

Повторяем попытку...

Скачать видео с ютуб по ссылке или смотреть без блокировок на сайте: Robotic Depalletizing for Distribution and Fulfillment Warehouses в качестве 4k

У нас вы можете посмотреть бесплатно Robotic Depalletizing for Distribution and Fulfillment Warehouses или скачать в максимальном доступном качестве, видео которое было загружено на ютуб. Для загрузки выберите вариант из формы ниже:

-

Информация по загрузке:

Скачать mp3 с ютуба отдельным файлом. Бесплатный рингтон Robotic Depalletizing for Distribution and Fulfillment Warehouses в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием видео, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса ClipSaver.ru

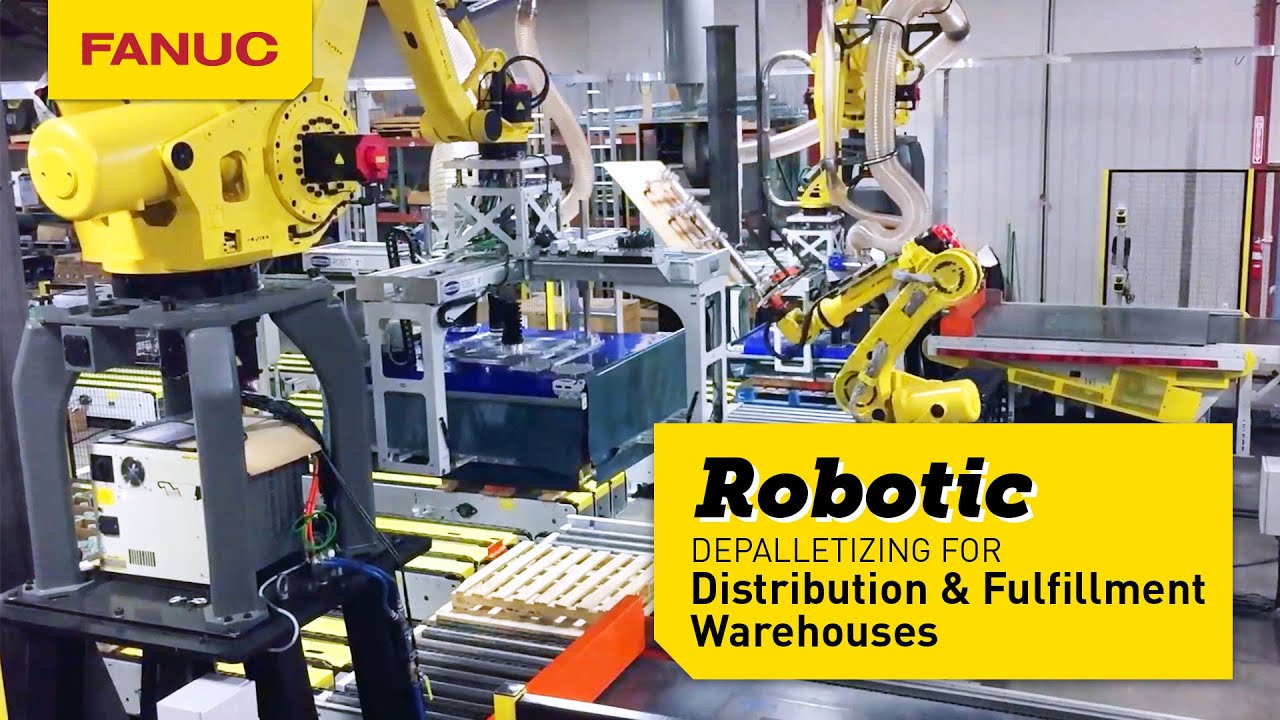

Robotic Depalletizing for Distribution and Fulfillment Warehouses

Motion Controls Robotics provides robotic depalletizing systems for manufacturing and distribution facilities. Motion Controls Robotics (MCRI) uses vision to assist with single case, row, or full layer depalletizing operations. Full layers can be depalletized at 4+ layers per minute using a full layer end of arm tool (600+ products per hour!). Robotic depalletizing can be used as part of a rainbow palletizing operation at the manufacturer’s facility or at co-packing sites. This allows mixed pallets of product to be sent to retail sites and/or loaded onto route delivery trucks. In a standard rainbow palletizing operation, up to four different types of products can be automatically depalletized and then repalletized to create a mixed pallet of products. Tier sheets can be automatically removed from the pallet load and placed into a recycling hopper or bailer in the depalletizing operation. Tier sheets can also be placed where required in the mixed product pallet as part of the robot operation. Features of Robotic Depalletizing: Vision is used to reliably locate “next pick” for the robot, whether the robot is picking full layers, rows, or individual products On-the-fly product teaching is possible for vision to simplify introduction of new product Rapidly, reliably, consistently remove product from an incoming pallet load Depalletized product can be repalletized in mixed pallet loads, or transferred to a powered take away conveyor for downstream labeling/processing, or placed directly into a sortation operation or storage/buffer area Incoming and outgoing empty pallets are automatically managed Empty pallets can be inspected after being emptied and sorted into “good” and “bad” pallet stacks Cases, bundles, trays, totes, pails, etc can all be robotically depalletized and repalletized in mixed / rainbow format Basic site requirements include: 480VAC, 3Ph power, 30 amps 80psi/50CFM air supply 8” thick, smooth, level concrete under robot Learn more about Motion Control Robotics, Inc.: https://motioncontrolsrobotics.com/ Learn more about the FANUC M-410 robot series: https://www.fanucamerica.com/products... Learn more about the FANUC R-2000 robot series: https://www.fanucamerica.com/products...