Скачать с ютуб What is Welding Defects – Types, Causes and Remedies? в хорошем качестве

Скачать бесплатно и смотреть ютуб-видео без блокировок What is Welding Defects – Types, Causes and Remedies? в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно What is Welding Defects – Types, Causes and Remedies? или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон What is Welding Defects – Types, Causes and Remedies? в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса ClipSaver.ru

What is Welding Defects – Types, Causes and Remedies?

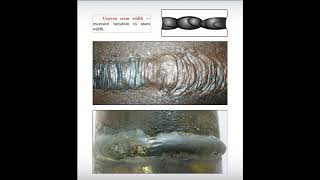

Welding Defects can be defined as the irregularities formed in the given weld metal due to wrong welding process or incorrect welding patterns, etc. Some defects are caused by problems with the materials. Other welding problems may not be foreseeable and may require immediate corrective action. A poor welding technique and improper choice of welding parameters can cause weld defects. Defects that can occur when using the shielded metal arc welding process are slag inclusions, wagon tracks, porosity, wormhole porosity, undercutting, lack of fusion, overlapping, burn through, arc strikes, craters and excessive weld spatter. Many of these welding technique problems weaken the weld and can cause cracking. Other problems that can occur and which can reduce the quality of the weld are arc blow, finger nailing and improper electrode coating moisture contents. To Join us on Facebook Please Click on Below Link / rizzu6699 To Join us On Telegram and get update on Mobile https://t.me/pipingengineeringworld