Understanding Industrial Automation Levels in Manufacturing: From Push Buttons to SCADA MES Systems скачать в хорошем качестве

Повторяем попытку...

Скачать видео с ютуб по ссылке или смотреть без блокировок на сайте: Understanding Industrial Automation Levels in Manufacturing: From Push Buttons to SCADA MES Systems в качестве 4k

У нас вы можете посмотреть бесплатно Understanding Industrial Automation Levels in Manufacturing: From Push Buttons to SCADA MES Systems или скачать в максимальном доступном качестве, видео которое было загружено на ютуб. Для загрузки выберите вариант из формы ниже:

-

Информация по загрузке:

Скачать mp3 с ютуба отдельным файлом. Бесплатный рингтон Understanding Industrial Automation Levels in Manufacturing: From Push Buttons to SCADA MES Systems в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием видео, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса ClipSaver.ru

Understanding Industrial Automation Levels in Manufacturing: From Push Buttons to SCADA MES Systems

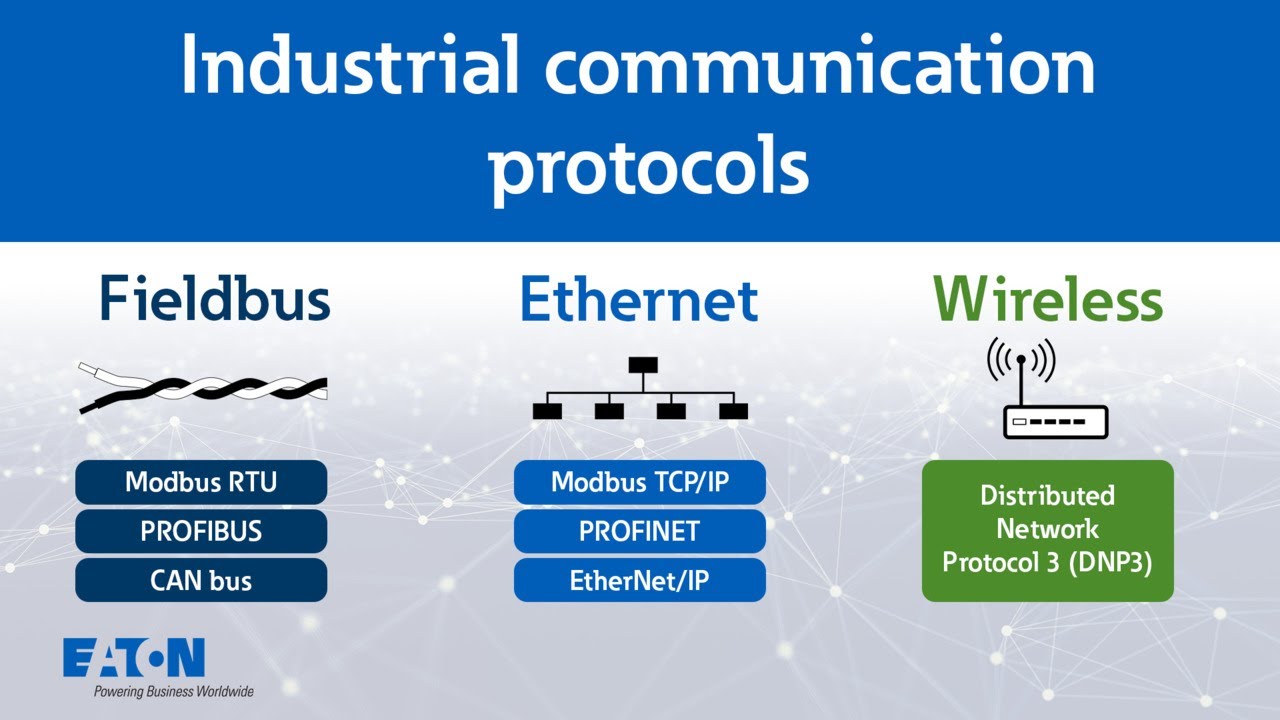

If you work in manufacturing and want to better understand where your facility stands from an automation perspective, this video is a complete walkthrough of real world automation layers. From the most basic controls like a simple start and stop pushbutton, to complex networks with SCADA systems, PLCs, VLAN segmentation, and cloud connectivity, I take you through every level I have personally seen in the field. We begin with foundational concepts. What does it look like when a facility has almost no automation beyond a contactor and a few pushbuttons. What are the risks of staying at this level. What drives the next step. From there we move into systems that introduce programmable logic controllers, HMIs, basic IO, and the concept of digital versus analog signals. You will learn how networking starts to play a role in control systems. We look at how distributed IO works, how VFDs and load cells can be integrated into a single panel, and when managed switches make sense. We break down examples of facility layout, how systems are scaled up using Ethernet, and what it means to interconnect different parts of the process using structured networks. This video also explains how facilities transition from local networks to plant wide infrastructure. We look at VLAN creation, how to segment devices, why duplicate IP addresses are dangerous, and how to avoid common network bottlenecks. Finally, we cover SCADA systems and MES platforms. What do they actually provide in terms of value. When should a facility consider implementing them. And how do you know if your team is ready to act on the data they provide. We finish with the highest level of integration including server rooms, remote access, cloud storage, and the path toward a modern smart factory. This video is designed for plant managers, operations leaders, electrical and automation engineers, and anyone who is trying to modernize systems in a practical and strategic way. If you have questions about your facility or want to explore automation strategy in more detail, leave a comment and I will do my best to help. 🕒 Timestamps 00:00 Introduction to manufacturing automation levels and why they matter 02:00 Basic automation using pushbuttons contactors and VFDs 04:30 Risks of minimal automation and when to upgrade 06:15 Introduction of PLCs HMIs and IO for process control 08:30 Digital versus analog signals and common IO setups 10:40 When to introduce distributed IO and panel level networking 13:30 How managed switches and industrial networks support larger systems 15:30 Building plant wide architecture with SCADA and interlocks 20:00 Network segmentation VLANs duplicate IPs and traffic isolation 30:00 Final thoughts on SCADA MES cloud and full facility integration