What is Electroslag Welding ? | ESW Welding | Vertical Welding скачать в хорошем качестве

Повторяем попытку...

Скачать видео с ютуб по ссылке или смотреть без блокировок на сайте: What is Electroslag Welding ? | ESW Welding | Vertical Welding в качестве 4k

У нас вы можете посмотреть бесплатно What is Electroslag Welding ? | ESW Welding | Vertical Welding или скачать в максимальном доступном качестве, видео которое было загружено на ютуб. Для загрузки выберите вариант из формы ниже:

-

Информация по загрузке:

Скачать mp3 с ютуба отдельным файлом. Бесплатный рингтон What is Electroslag Welding ? | ESW Welding | Vertical Welding в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием видео, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса ClipSaver.ru

What is Electroslag Welding ? | ESW Welding | Vertical Welding

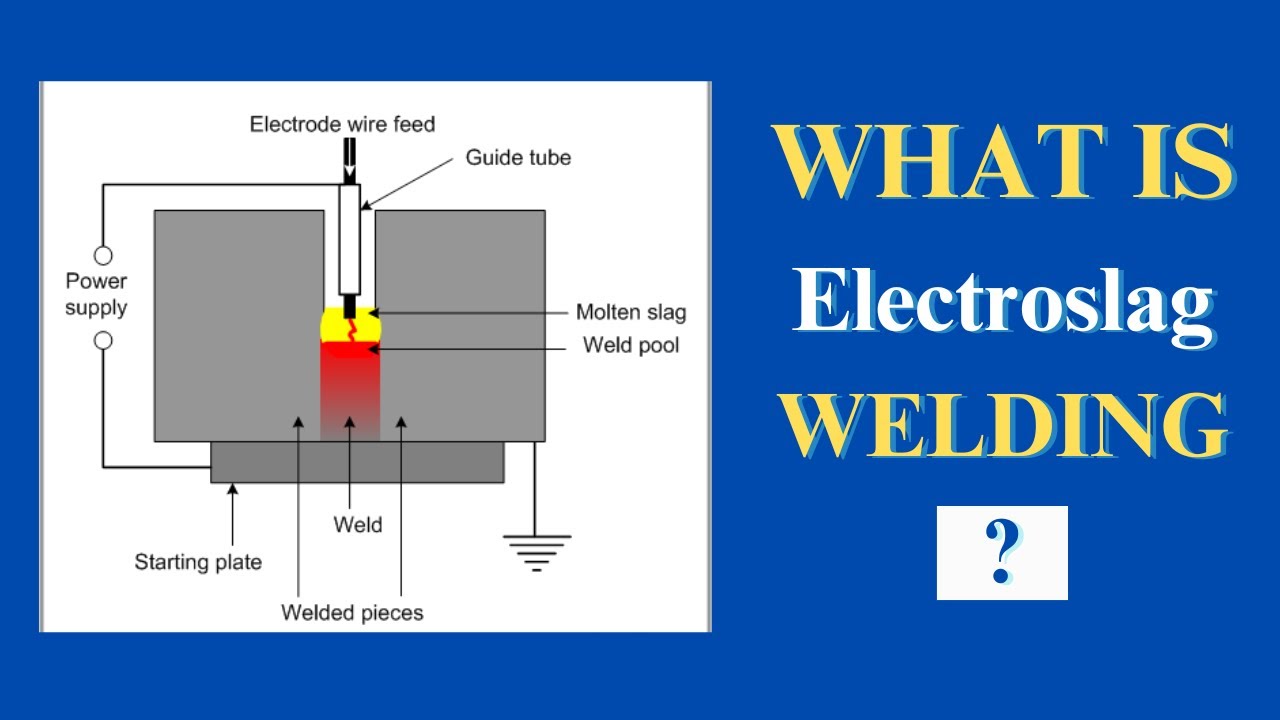

Electroslag Welding (ESW): Complete Guide to High-Efficiency Vertical Welding 🔧 Time Stamps: 0:00 – Introduction 0:54 – Diagram 1:07 – Equipment 3:03 – Working Principle 3:50 – Steps Involved 5:10 – Applications 5:49 – Advantages 6:11 – Disadvantages 6:35 – Safety Considerations 7:26 – Thank You 1. What is Electroslag Welding (ESW)? Electroslag Welding (ESW) is a high-efficiency welding process that is primarily used for vertical joints on thick materials. Unlike traditional welding processes, ESW uses an electric arc to generate heat that melts the metal, and the molten metal fills the joint gap while a layer of molten flux covers the weld pool, protecting it from atmospheric contamination. Ite process is designed for high-deposition-rate welding, ideal for welding thick plates in a single pass, making it incredibly time-saving and economical for large-scale industrial projects. 2. How Electroslag Welding Works: In ESW, the process begins with striking an arc between a wire electrode and the base metal. However, once the slag reaches the desired temperature, the arc is extinguished, and the electroslag process takes over, where electrical resistance heats the slag, melting the electrode and the surrounding base material. The weld pool remains shielded from oxidation and contamination by a blanket of molten slag, resulting in a clean weld. ESW is typically used for vertical welding, allowing for single-pass welds on thick plates up to several inches thick. 3. Key Electroslag Welding Equipment: Power Source: Supplies the electrical current needed for melting the electrode and generating the heat. Wire Electrode: Continuously fed into the joint to supply the filler metal for the weld. Water-Cooled Copper Shoes: These act as molds on either side of the weld, helping to contain the molten metal and control the shape of the weld. Welding Flux: Forms a molten slag layer that protects the weld pool from the atmosphere and adds insulation. Welding Controller: Regulates the electrode feed rate, current, and other parameters to ensure consistent welding. 4. Advantages of Electroslag Welding: High Efficiency: Deep Penetration: Minimal Distortion: Excellent Weld Quality: Cost-Effective for Large Projects: 5. Disadvantages of Electroslag Welding: Limited to Vertical Welds: ESW is primarily used for vertical joints, so it’s not suitable for horizontal or overhead welding applications. High Equipment Costs: The specialized equipment needed for ESW, including copper shoes and heavy-duty power sources, can be costly. Not Ideal for Thin Materials: ESW is best suited for thick plates and heavy-duty welds; it’s not suitable for thin or delicate materials. Risk of Slag Entrapment: If not properly controlled, the slag can become trapped in the weld, leading to defects. 6. Applications of Electroslag Welding: Shipbuilding: ESW is used for welding large, thick sections of steel in shipbuilding, such as hulls and decks. Structural Steel: Commonly used in the construction of bridges, skyscrapers, and other large-scale structures that require vertical welds on thick steel plates. Pressure Vessel Manufacturing: ESW is ideal for pressure vessels and boilers, where thick, high-strength materials need to be welded together efficiently. Heavy Equipment Manufacturing: Large machinery and industrial equipment made from thick steel plates can benefit from the efficiency and strength of ESW welds. Nuclear Power Plants: ESW is used in the construction of nuclear reactors, where thick-walled components and minimal defects are critical. 7. Step-by-Step Electroslag Welding Process: Step 1: Prepare the Joint—Set up the vertical joint between the thick plates, ensuring the surfaces are clean and ready for welding. Step 2: Set Up the Copper Shoes—Attach water-cooled copper shoes to either side of the joint to form a mold for the molten metal. Step 3: Start the Welding Process—Strike the initial arc to melt the electrode and the base material, generating the molten pool. Step 4: Slag Formation and Welding—Once the molten slag forms, extinguish the arc, and rely on electrical resistance to maintain the molten state. The weld pool will fill the joint as the electrode continuously melts. Step 5: Complete the Weld—Continue the process until the weld joint is filled from the bottom to the top. Allow the weld to cool and remove the copper shoes. Step 6: Inspect the Weld—Check the weld for defects such as slag inclusion, porosity, or incomplete fusion. Regards SAGAR KUMAR #ElectroslagWelding #ESWWelding #VerticalWelding #HighEfficiencyWelding #IndustrialWelding #HeavyDutyWelding #ShipbuildingWelding #StructuralSteelWelding #WeldingTechniques #WeldingSafety #WeldingProcess #WeldingTips #ConstructionWelding #WelderCommunity #ESW #VerticalWelding