Скачать с ютуб How the THERMOFORMING PROCESS works? - Factories в хорошем качестве

Thermoforming technology

thermoforming

plastic

vacuum forming

production

cnc

packaking design

packages

food industry packaging

food industry

forming station

production line

packaging

food

cosmetic

automotive

technical

poli

poland

how its made

how it's made

factory

factories

production plants

industry

production process

documentary film

how the thermoforming process works

diy

how to

how to make

discovery

manufacturing

cnc machine

how stuff works

tesla

Скачать бесплатно и смотреть ютуб-видео без блокировок How the THERMOFORMING PROCESS works? - Factories в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно How the THERMOFORMING PROCESS works? - Factories или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон How the THERMOFORMING PROCESS works? - Factories в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

How the THERMOFORMING PROCESS works? - Factories

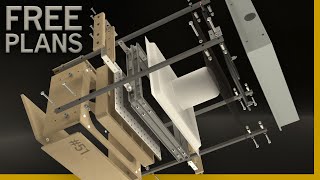

Thermoforming technology involves obtaining a desired shape by heating and forming a plastic film or plastic cut-sheets. It is an interesting but not easy process, and it requires a lot of experience. Thanks to this technology you can also find a lot of packaging on store shelves. Today we will see how the thermoforming process works. For this purpose we are visiting the production facilities of the family company Poli www.poli.com.pl First, we are visiting the Product Design Department, because this is where every project begins. Here all projects of packaging that have to be implemented in production are born. After accepting the packaging design, it is time to prepare the design of tooling which will be used to produce the item. The tooling is created in the CNC department on numerically controlled machines. The complete tool consists of the forming station including mould, plug assist and cooling system as well as cutting station and stacking station. However, the main part of the tooling is where the shape of the product is created. In this part, vaccuml holes of 0.4 mm diameter are drilled. Through them the thermoplastic material is sucked into the mould surface. The holes are so small that they are not visible on the packaging. With the finished tool ready, production can begin. First, we will see how small packaging for the food industry is produced. The film is unrolled and then heated at the first two stations. The temperature of about 200 degrees Celsius makes the film malleable. Then it goes to the forming station. The material is initially stretched and shaped with pressure and vacuum. The material cools down and thus the shape of the detail is preserved. In the next station, individual products are cut out with the die cut. Next, they are picked up and placed by a robot. The moment of forming of the product is clearly visible in machines which produce large-sized thermoformed elements. The product is made of polycarbonate cut-sheet of about 8 mm thickness. The raw material has high transparency, just like glass. The cut-sheet is heated on both sides. Then, with a blow the flexible material is vacuum sucked into the mould. On a cold form, the material stabilizes. Cooling takes about 180 seconds. After collection from the line, the CNC machine cuts off the excess and mills the edges. On this production line, packaging from printed film is produced. In one cycle, packages of 8 different types of product are produced. In order to keep up with the speed of production, the robot picks parts from two cycles simultaneously. Safe stacking system is used here, so that the packaging does not stick to each other. Finally, the products are separated into eight different lines and transported for packing. As part of the thermoforming process, a so-called skeleton is created. It is then transferred to grinders as post-production waste, and in the form of flake used again to produce film. Finished products go to the Quality Control Department, which monitors the entire production process. We measure, among other things, dimensions of the finished packaging. When examining the raw material, we also check the coefficient of friction. The product must have a certain slide, which is extremely important in the automatic packaging process. Poli produces packaging with a thickness of 0.15 mm to 12 mm. They are used in industries such as food, cosmetics, pharmaceutical, technical and automotive. --- Factories is a journey through production plants. We are visiting industry. We were inspired by the popular program "How is it made?" Known from the Discovery television channel. Every week, together with our viewers, we visit the production plant to check how the selected production process is going. Every week, our channel receives a documentary film, from which you learn how things are produced. Among others machines, rope slings, yachts, wires, windows, railroad switches, radiators, polystyrene etc. You are probably also interested in how food is made? On our channel we showed, among others frankfurters, Pepsi, kebab, salty sticks, mustards, ketchup, mayonnaise, cheese and many more. It's amazing how exciting production can be. Science and technology carry so much interesting information. Every week you get to know with us the curiosities of factories. The factory has no secrets for us.