Extraction of Iron in Malayalam/Chemistry скачать в хорошем качестве

Повторяем попытку...

Скачать видео с ютуб по ссылке или смотреть без блокировок на сайте: Extraction of Iron in Malayalam/Chemistry в качестве 4k

У нас вы можете посмотреть бесплатно Extraction of Iron in Malayalam/Chemistry или скачать в максимальном доступном качестве, видео которое было загружено на ютуб. Для загрузки выберите вариант из формы ниже:

-

Информация по загрузке:

Скачать mp3 с ютуба отдельным файлом. Бесплатный рингтон Extraction of Iron in Malayalam/Chemistry в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием видео, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса ClipSaver.ru

Extraction of Iron in Malayalam/Chemistry

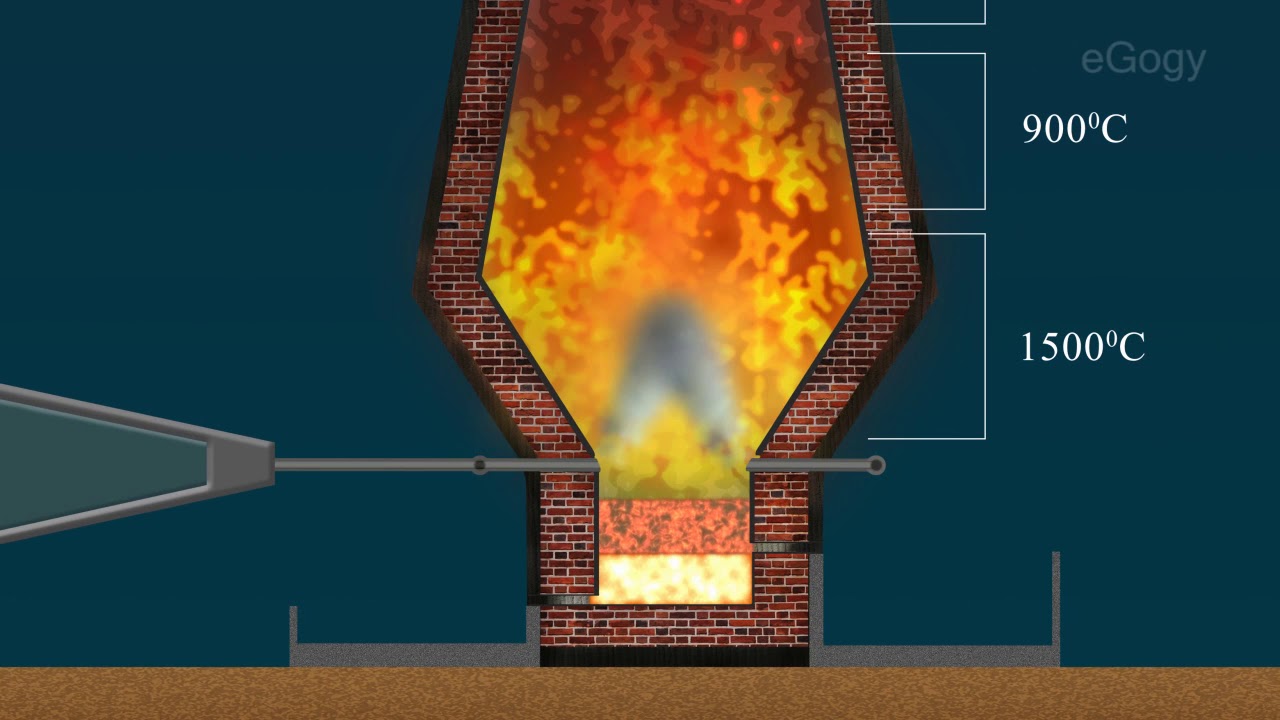

The iron ore is converted to iron in a blast furnace. This is made of steel in which the inner side is covered using bricks. The mixture of concentrated ore, coke and limestone are added from the top in to the blast furnace. A powerful current of hot air is blown from the bottom simultaneously. During the flow of hot air from bottom to top, coke combines with oxygen in the air to form carbon monoxide. 2C +O2 2CO Due to this reaction, the large amount of heat is released and thus the temperature of blast furnace increases to 2000*c. Carbon monoxide formed in the furnace reduces the ore. Fe2O3 +3CO 2Fe +3CO2 At high temperature calcium carbonate decomposes to form calcium oxide and carbon dioxide. CaCO3 CaO + CO2 Then impurity, silicon dioxide in the ore reacts with calcium oxide and form calcium silicate which is known as slag. CaO + SiO2 CaSiO3 Flux + gangue slag The iron obtained directly from blast furnace is called as pig iron. It contains carbon, sulphur, phosphorous, manganese, silicon etc in very small quantities. Pig iron is heated to melting and again solidified to get cast iron. In cast iron.95% is iron. The iron which contains 0.1% - 1.5% of carbon is called steel.