Fully Automatic Inductor Bobbin Coil Winding & Soldering Machine in India – Complete Production Line скачать в хорошем качестве

Повторяем попытку...

Скачать видео с ютуб по ссылке или смотреть без блокировок на сайте: Fully Automatic Inductor Bobbin Coil Winding & Soldering Machine in India – Complete Production Line в качестве 4k

У нас вы можете посмотреть бесплатно Fully Automatic Inductor Bobbin Coil Winding & Soldering Machine in India – Complete Production Line или скачать в максимальном доступном качестве, видео которое было загружено на ютуб. Для загрузки выберите вариант из формы ниже:

-

Информация по загрузке:

Скачать mp3 с ютуба отдельным файлом. Бесплатный рингтон Fully Automatic Inductor Bobbin Coil Winding & Soldering Machine in India – Complete Production Line в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием видео, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса ClipSaver.ru

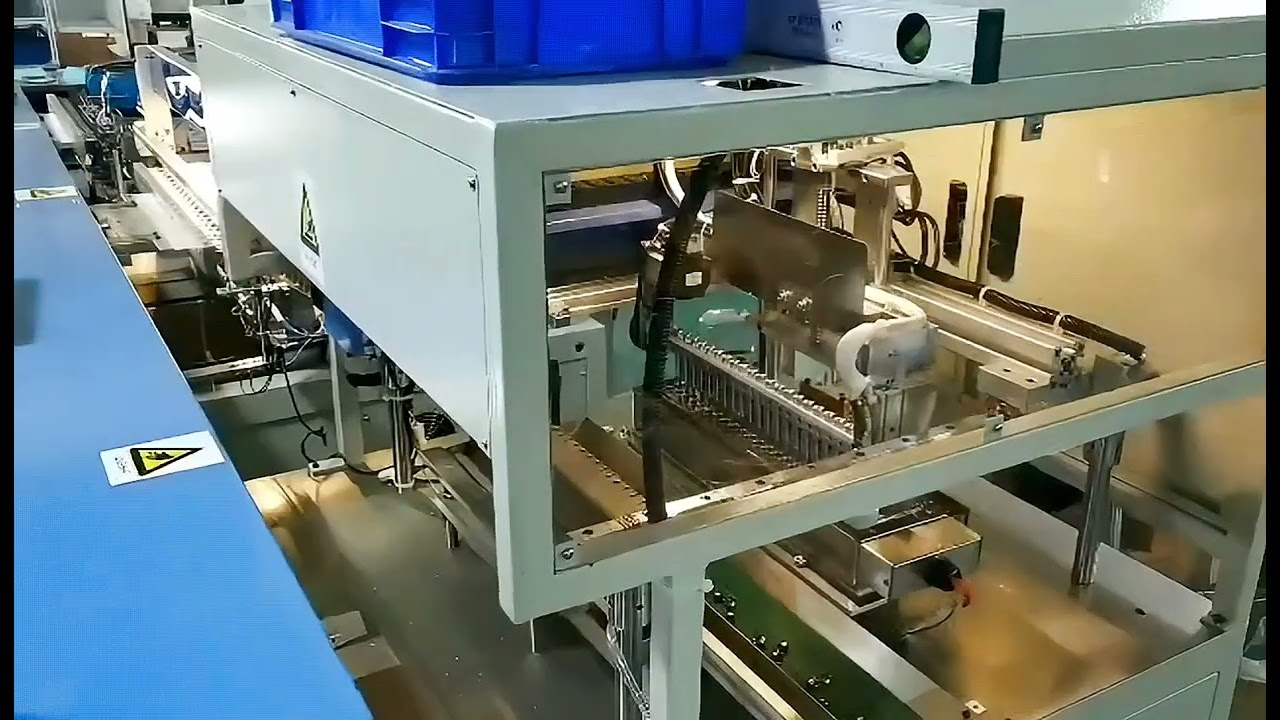

Fully Automatic Inductor Bobbin Coil Winding & Soldering Machine in India – Complete Production Line

In today’s fast-growing electronics manufacturing industry, automation plays a vital role in improving quality, speed, and efficiency. One of the most advanced solutions in this segment is the Automatic Inductor Bobbin Coil Winding Machine Production Line, designed specially for high-speed and high-volume coil manufacturing. 1. Introduction to Automatic Inductor Winding Production Line : The Automatic Inductor Bobbin Coil Winding Machine is a state-of-the-art production line that handles the complete coil manufacturing process — from bobbin feeding to soldering — without any manual intervention. It is ideal for producing ferrite inductors, transformer coils, and similar winding components in mass production environments. The system ensures uniform quality, high precision, and excellent repeatability, which are critical for maintaining consistency in modern electronics production. 2. Fully Automated Bobbin Feeding System : The process begins with an automatic bobbin feeding system, which uses a vibrator bowl to feed bobbins continuously and automatically. This eliminates the need for manual handling and ensures smooth, uninterrupted production. Each bobbin is oriented perfectly before entering the winding station, ensuring flawless alignment and accuracy during the winding process. 3. Automatic Bobbin Loading to Winding Machine : After feeding, the system automatically loads each bobbin into the winding machine. This auto-loading mechanism not only saves labor but also minimizes human error, ensuring that every bobbin is placed in the exact position for winding. The seamless coordination between the feeder and winding machine allows continuous operation for long hours, ideal for large-scale production lines. 4. 12-Spindle High-Speed Winding Machine : At the heart of the production line lies the 12-spindle high-speed precision winding machine. This machine can wind 12 pieces of coils in one single cycle, offering tremendous output and efficiency compared to conventional single-spindle machines. If the product design requires insulation taping after winding, an optional taping attachment can be integrated directly into the line for an all-in-one solution. 5. Automatic Unloading and Transfer to Soldering Station : Once winding is completed, the system automatically unloads the finished coils and transfers them to the soldering station. This robotic material transfer eliminates the need for manual handling, thus maintaining product cleanliness and preventing coil damage. 6. Auto Flux Dip & Auto Solder Dip System : At the soldering station, the coils undergo auto flux dipping followed by auto solder dipping. This dual-stage process ensures strong, clean, and reliable solder joints on each coil pin. 7. Optional Automation Extensions : Depending on production requirements, additional automation modules can be integrated — such as: Core assembly station for inserting ferrite cores into the coils Core taping machine for insulation and secure core fixing LCR automatic testing machine for quality checking and parameter verification These modules help complete the entire coil production line from start to finish, turning it into a fully autopilot manufacturing system. 8. Ideal for Mass Production in India This machine line is ideal for mass manufacturing of inductor or transformer ferrite coils used in SMPS, adapters, chargers, and electronic devices. It delivers consistent quality output and drastically reduces manpower requirements. Many reputed companies in India have already installed this system and are benefiting from higher productivity, better accuracy, and faster ROI. 9. Why Choose Deptronics Technologies Deptronics Technologies is recognized as one of the most trusted automation partners in India for coil winding and transformer production lines. We offer complete solutions from machine selection, installation, and programming to operator training and after-sales service. Our support covers: All over India installation & commissioning Comprehensive training and operational guidance Maintenance and technical support Warranty and spare parts availability ✅ Ready to Automate Your Coil Manufacturing in India? 📞 Contact : DepTronics Technologies 🌐 https://coilwinder.in/ 📧 sales.deptronics@gmail.com 📱 +91-8800622761 #InductorWindingMachine #AutomaticCoilWindingMachine #FerriteCoreCoil #TransformerWindingMachine #AutomaticSolderingMachine #DeptronicsTechnologies #CoilWinderIndia #MassProductionLine #SMPSCoilManufacturing #AutomationInIndia #bobbinwindingmachine