Electroslag Welding (ESW) for Rebar/Resistance welding скачать в хорошем качестве

Повторяем попытку...

Скачать видео с ютуб по ссылке или смотреть без блокировок на сайте: Electroslag Welding (ESW) for Rebar/Resistance welding в качестве 4k

У нас вы можете посмотреть бесплатно Electroslag Welding (ESW) for Rebar/Resistance welding или скачать в максимальном доступном качестве, видео которое было загружено на ютуб. Для загрузки выберите вариант из формы ниже:

-

Информация по загрузке:

Скачать mp3 с ютуба отдельным файлом. Бесплатный рингтон Electroslag Welding (ESW) for Rebar/Resistance welding в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием видео, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса ClipSaver.ru

Electroslag Welding (ESW) for Rebar/Resistance welding

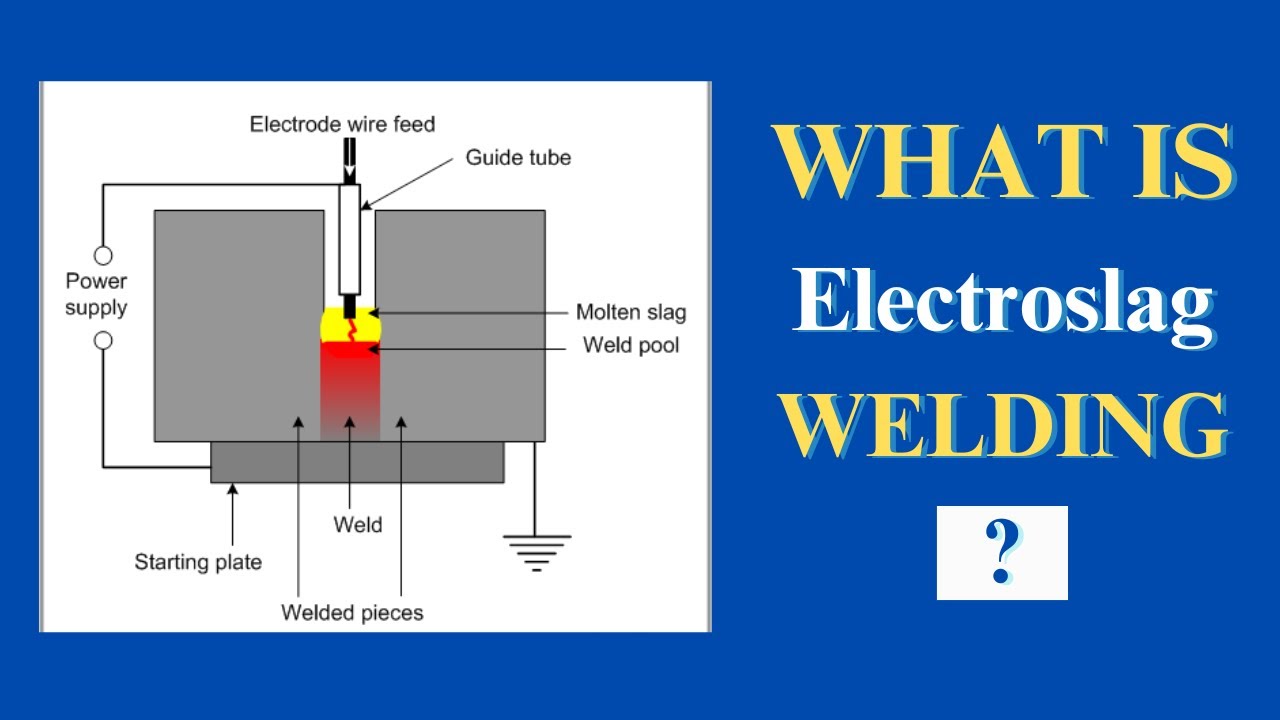

In civil engineering, the overlapping of rebars with melting steel particles and electrodes typically refers to a welding technique used to join reinforcing bars (rebars) in concrete structures. This process is commonly known as "resistance welding" or "electrode welding." Here's a general overview of how it works: 1. The rebars to be joined are overlapped at the desired location. 2. An electrode is placed in contact with the overlapping rebars. 3. Electrical current is passed through the electrode, creating resistance and generating heat. 4. The heat melts the steel particles at the interface of the rebars, causing them to fuse together. 5. Once the molten steel cools and solidifies, a strong weld joint is formed. This welding technique is often used in construction to ensure the structural integrity of concrete elements, such as beams, columns, and slabs. It provides a reliable connection between the rebars, allowing them to work together and transfer loads effectively. It's important to note that specific welding procedures and requirements may vary depending on the type and size of the rebars, the application, and local building codes and standards. Welding should typically be carried out by qualified and experienced welders following proper safety precautions. If you need more detailed or specific information about this topic, it's recommended to consult with a professional civil engineer or refer to relevant engineering textbooks, codes, or industry guidelines. They will be able to provide you with more accurate and in-depth information based on your specific needs.